Achieving Compliance Management and Safety

Globalisation and the need for compliance management has resulted in farmers and food and drink producers investing in technology, and advanced software solutions.

As standards and technology advance, compliance management managed by these methods must do so too. While machinery becomes more intelligent and more interconnected, there is a role for technology to manage the process of compliance.

An incredible new phase exists in the Food and Beverage Industry due to consumer demands, such as food being naturally produced, good for the environment and nutritional, are meeting modern technology. Recent technologies designed to interface with food production at every point in the process from farm to fork, are growing.

Enterprise Resource Planning (ERP) software brings almost real-time data on food quality and regulatory compliance management to the user. Blockchain technology can now track crop lifecycle from the moment farmers have planted crops, right to the consumer. This provides transparency across the entire supply chain.

Technology continues to expand beyond the confines of the factory floor to the very moment a farmer plants a seed, until food is served on the consumer’s plate.

The Food and Beverage industry, like all industries, has growingly become more defined by robotics and automation and it can expect to become more reliant on automation due to increased regulation.

The Importance of Safety for the Workforce

There is a moral and legal duty to safeguard Food and Beverage workers. Dangers vary from heavy equipment and toxic chemicals to dust inhalation and overuse strain injuries.

The most important tasks for management for health and safety are to:

- Maintain records of risks and accidents.

- Keep an up to date record of all equipment and the software that runs on it.

- Train safety personnel to the correct level of competency.

- Have all information available so that workers follow the correct accident prevention procedures and methods produced.

- Ensure workers follow industry safety regulations and inform every part of the process and working environment.

The Asset Guardian Solution

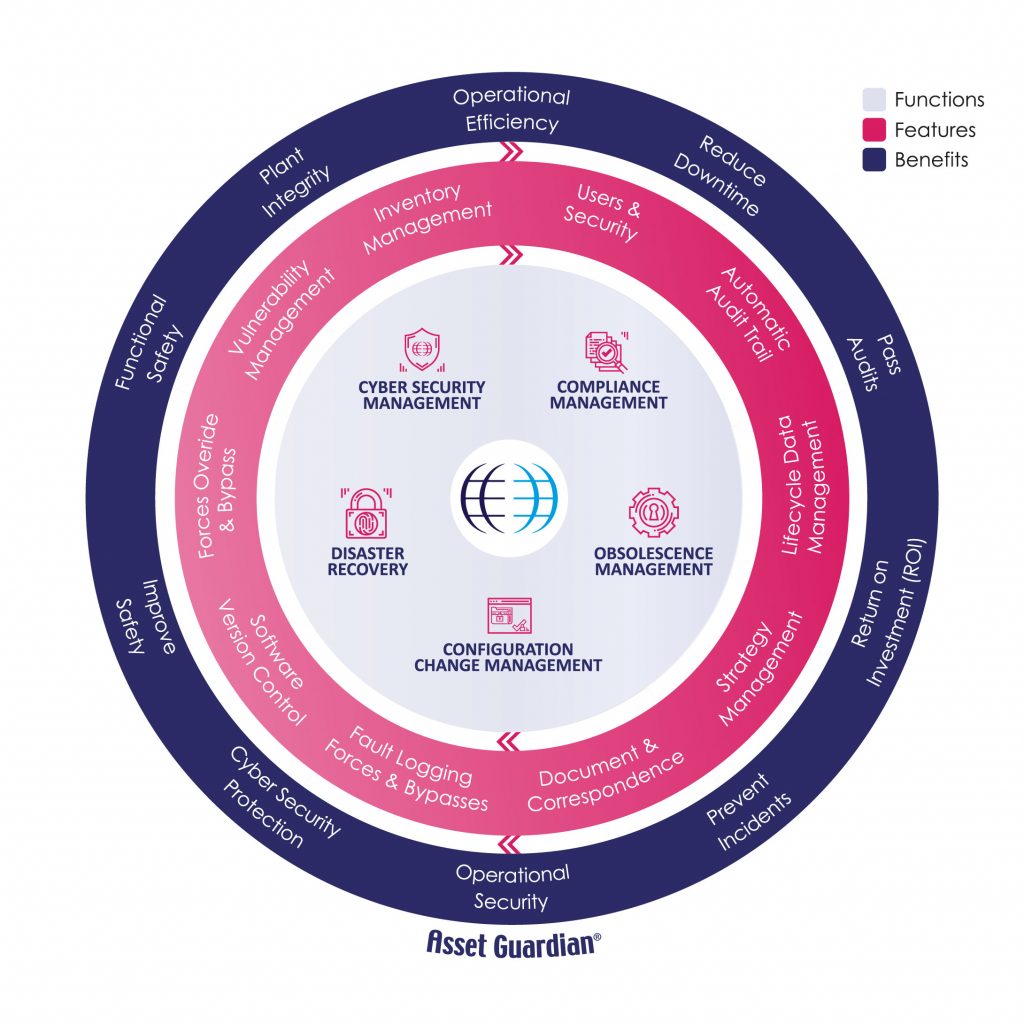

Asset Guardian can assist with the drive on regulation and technology by providing the following:

- Fully integrated suite of Change Management, Fault Logging, Document & Correspondence recording, and Software and Hardware Control tools.

- A full audit trail of every action taken in Asset Guardian.

- All Software logged into Asset Guardian as part of a change control process as part of the client’s Disaster Recovery Plan.

- Personnel and Competency recording and tracking.

- Analytics Data to improve, develop and maintain processes.

- By regularly assessing updated and new regulations and checking for compliance management.

Compliance Management in the Food and Beverage Industry with Asset Guardian

The biggest burden on the Food and Beverage industry is not environmental, but bureaucratic issues. Increased overheads continue to push already ultra-thin margins due to regulation. Major factors include stringent hygiene and safety standards, product waste prevention and the need for transparency across the whole supply chain.

Safety, managed through compliance to regulations, has more focus than ever before. While this is clearly the right way forward, it is undeniable that this is increasing pressure on the Food and Beverage industry. The good news is that Asset Guardian can help alleviate this pressure.

This is a transformative time for the Food and Beverage industry as it integrates 21st century technology into production and manufacture.

If you would like to discuss further how Asset Guardian can help you in the Food and Beverage Industry, please reach out to us today.

Written by Graham Foss. As one of AGSL’s team of Technical Consultants, Graham Foss is responsible for implementing the company’s product development and technology strategy. Before joining AGSL in 2016, Graham was employed for 12 years as a lead software engineer at Aker Solutions Subsea Ltd, where he worked on projects in the North Sea, North Atlantic and Norway. Graham holds a degree in Computing from Edinburgh’s Napier University in Edinburgh, where he graduated with distinction. A Chartered Engineer, he is a member of the Institution ofEngineering and Technology (IET).